How is DNO different from conventional photocatalytic oxidation (PCO) and UV systems?

18 February 2026

Key points

-

- Filters remove; catalysts can destroy. Passive filtration captures particles but does not chemically neutralise them; catalytic layers are designed to inactivate or break down captured material at/near the surface.

- UVGI (ultraviolet germicidal irradiation) or ‘UV‘ systems use ultraviolet light to inactivate microbes, and performance depends on delivered UV dose (intensity × time). Some UV lamp types can generate ozone if ozone-producing wavelengths are present.

- PCO (photocatalytic oxidation) uses UV + a catalyst surface to oxidise gases, but incomplete oxidation can form intermediate by-products in some designs and conditions.

- DNO (D-orbital nano oxide) is intended as surface-confined catalysis, pollutants are trapped at the catalyst surface and oxidised there, rather than creating reactive chemistry throughout the room air.

- By-products are the main differentiator. UV/PCO systems can generate partial oxidation products if reactions do not run to completion, and some UV lamp types can generate ozone if the wrong wavelengths are present.

- The correct comparison is not “does it work?” but “what does it remove, what does it create, and how do we know?”

When building teams compare air cleaning technologies, they often compare a single outcome (for example, particle reduction). That can be misleading, because UV- and oxidation-based approaches can also change indoor chemistry. The side effects of secondary air pollution can matter as much as the intended removal, and are often what differentiates one method from another in real buildings.

This article compares three common mechanisms: UV, PCO, and DNO.

The goal is to give a clear framework for understanding how each works, where by-products can come from, and what to ask for when you review test data.

What are UV, PCO and DNO trying to achieve indoors?

Indoor air contains a mixture of particles, gases, and bioaerosols. Each technology family tends to be strongest in one area:

-

UV: targets bioaerosols (inactivation under a defined UV dose).

-

PCO: aims to oxidise some gases/VOCs, and may also inactivate microbes at a catalyst surface.

-

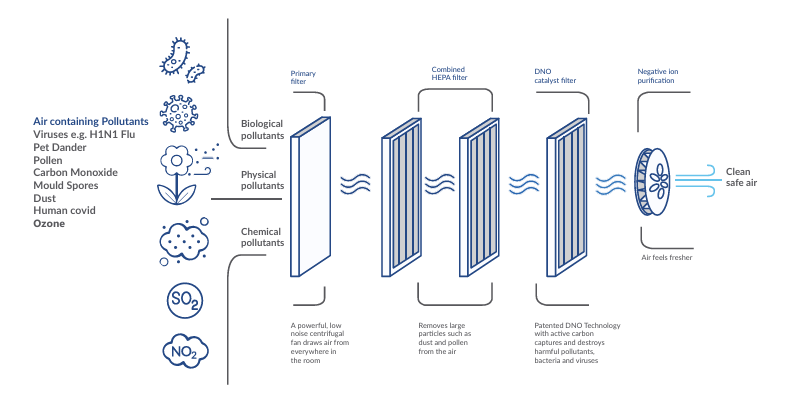

DNO: aims to oxidise pollutants at a catalyst surface and is typically combined with high-efficiency filtration for particulates, targeting bioaerosols, gases and particles.

For a refresher on pollutant groups and how they are typically measured, see:

Indoor air pollutants in modern buildings

How does UV work, and what are its limits?

UV air cleaning refers to the use of an ultraviolet light to inactivate microorganisms as air (or surfaces) passes through an irradiated zone.

Where UV systems fit well

This method is most controllable when the system forces air through a defined zone, such as:

-

-

in-duct UV systems, or

-

engineered upper-room UVGI installations.

-

What UV does not solve by itself?

-

Gases and VOCs: UVGI is not a gas adsorption system. Some UV configurations can influence VOC chemistry, but that is not the same as consistently removing VOCs to stable end products.

-

Particles: UV does not “filter” dust or smoke; you still need mechanical filtration for that.

The by-product question for UV

Some UV lamp types can also generate ozone at certain wavelengths. In well-designed UVGI products, this is usually controlled by lamp materials or coatings, but it is reasonable to ask for measured ozone data in the intended operating mode.

How does PCO differ from UVGI?

PCO combines UV light + a catalyst surface (commonly titanium dioxide, TiO₂). UV energises the catalyst and creates reactive species at the surface that can oxidise organic compounds.

What PCO is aiming to do

-

Oxidise VOCs and some odorous compounds.

-

Inactivate microbes at or near the irradiated catalyst surface.

Why incomplete oxidation matters

The key issue is reaction completeness. In laboratory settings, it is possible to fully oxidise VOCs to carbon dioxide and water (“mineralisation”). In real-world settings, however, the contact time and surface conditions may not be sufficient for complete conversion.

Peer-reviewed studies on UV-PCO have reported intermediate or partial oxidation products, including aldehydes such as formaldehyde or acetaldehyde. Even when these by-products are produced at low levels, they matter because indoor air is already a complex chemical environment.

The by-product question for PCO

If a system claims VOC “destruction”, ask for test data that includes:

-

inlet/outlet VOC measurements (not only “TVOC”),

-

measurements of common intermediates (often aldehydes), and

-

ozone measurements if UV lamps are involved.

What is DNO doing differently?

DNO is described as catalytic oxidation at room conditions. It is designed to activate oxygen at the surface and use that surface-bound reactive oxygen to oxidise adsorbed pollutants.

A simple way to summarise the mechanism is:

-

pollutants are captured at or near a catalytic surface,

-

oxygen is activated at that surface,

-

oxidation happens at/near the surface, and

-

the system aims to avoid relying on reactive chemistry circulating through the occupied room air

How does DNO compare to UV and PCO in an occupied room?

The table below is a comparison of typical characteristics; individual products vary and should be evaluated on data.

| Technology | Main “engine” | Primary strengths | Main limitations | What to check in test data |

|---|---|---|---|---|

| (UVGI) | UV dose (irradiance × time) | Microbial inactivation when dose and airflow are controlled | Does not remove particles; limited direct gas removal | UV dose method, safety design, ozone, real-world airflow conditions |

| UV-PCO | UV + photocatalyst | Can oxidise some VOCs and inactivate microbes near a surface | Risk of incomplete oxidation and by-products; performance depends on residence time, humidity, VOC mix | Aldehydes/by-products, ozone, inlet/outlet chemistry, performance at realistic concentrations |

| DNO (catalytic) | Surface oxygen activation | Designed for surface-confined oxidation; integrated with particle filtration | Depends on surface condition, contact time, and maintenance | Evidence of pollutant removal and absence of harmful by-products; maintenance |

Why “secondary pollution” is the hinge point in these comparisons

“Secondary air pollution” is a useful concept because it forces a more complete evaluation:

-

What did the device remove?

-

What did the device create or re-release?

With UV and UV-PCO, by-products are not guaranteed, but they are a potential risk that good evaluations should check. With any oxidation-based approach, the meaningful question is whether measurements show pollutant reduction without introducing new indoor pollutants under realistic operating conditions.

What does “good evidence” look like when you compare DNO, UV and PCO?

A technology-neutral checklist:

1) Which pollutants does the technology address?

-

Particles (PM₂.₅ / PM₁₀): you will need mechanical filtration.

-

VOCs/odours: look for gas-phase data and whether the system is designed for adsorption, destruction, or both.

-

Bioaerosols: ask how inactivation is measured (culture-based, molecular methods, surrogate organisms).

2) Were by-products measured?

You should expect to see explicit measurements for:

-

ozone

-

aldehydes / partial oxidation products

3) Is the testing realistic?

Prefer data that includes:

-

an environmental chamber or controlled test setup (repeatable)

-

field measurements in an occupied setting (real-world)

-

clear “device on vs off” comparisons over time

How should you decide between DNO, PCO and UV in practice?

If you are choosing between these approaches for an occupied building:

-

Use ventilation and filtration as your foundation for particle control (PM₂.₅ and PM₁₀).

-

Add targeted methods for the pollutant that matters most in your building:

-

Microbial control focus → UVGI may be appropriate if engineered properly.

-

VOC/odour focus → adsorption + oxidation approaches may be considered, with consideration of by-product data.

-

-

Prioritise technologies that show pollutant reduction without creating new indoor pollutants at the operating settings used when people are present.

Air cleaning should be evaluated the same way other building systems are evaluated – by the combination of mechanisms, controls, and measured outcomes.

To find out more about how these technologies fit together, see: How Indoor Air Purification Technologies Work.

Summary

UVGI, UV-PCO, and DNO all involve “active” processes, but they work differently. UVGI is primarily a disinfection method driven by UV dose. UV-PCO adds a photocatalyst and aims to oxidise VOCs, but can form intermediates if oxidation is incomplete. DNO is presented as a surface-confined catalytic method intended to keep reactive chemistry on a solid surface rather than in the occupied air volume.

Suggested next reads in this Knowledge Hub

Latest News

How is DNO different from conventional photocatalytic oxidation (PCO) and UV systems?

Key points Filters remove; catalysts can destroy. Passive filtration captures particles but does not chemically neutralise them; catalytic…

How do D-orbital nano oxide (DNO) catalysts work in air purification?

Key points D-orbital nano oxide (DNO) describes a family of transition-metal oxide catalysts used to break down some…

How do different indoor air purification technologies actually work?

Key points “Air purification” is not one technology: different systems target particles, gases/VOCs, and bioaerosols in different ways….